Description

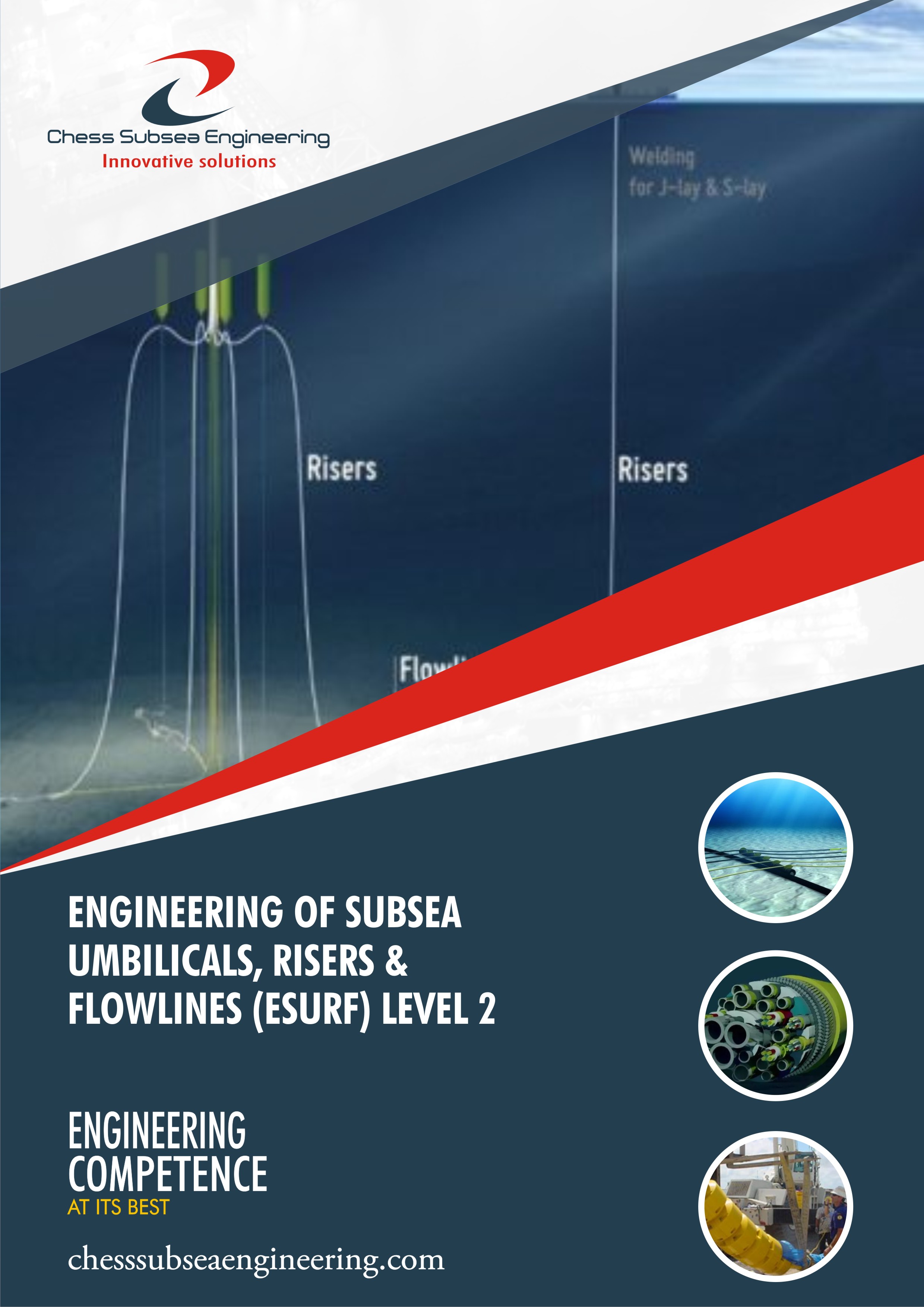

Subsea, umbilicals, risers, and flowlines (SURF) refer to the complex network of underwater infrastructure that connects offshore production facilities to the shore or other infrastructure. These systems are used in the offshore oil and gas industry to transport oil, gas, and other fluids from offshore wells to onshore processing plants or other subsea infrastructure.

SURF systems are designed to withstand the harsh environmental conditions of the offshore environment, including high pressures, extreme temperatures, and corrosive seawater. The design and installation of SURF systems require specialized knowledge and expertise in areas such as structural engineering, mechanical engineering, and subsea pipeline engineering. SURF systems are critical to the success of offshore oil and gas production, as they enable the safe and efficient transportation of oil and gas from the seabed to onshore processing facilities.

This course covers Subsea Flexible Pipe, Types of Flexible Pipe, Comparison of Flexible Pipe Types, Flexible Pipe Application, Advantages of Flexible Pipe, Flexible Pipe Limits, Flexible Pipe Configurations, Flexible Pipe Material Selection, Flexible Pipe Layer Function, Ending Fitting Design critical Issues, Design Process , Functional Requirements, Design Codes & Criteria, Structural Cross-Section Design & Analysis, Structural Cross-Section Design Models Advantages & Disadvantage, Structural Layers Engineering Design Calculations & Verification, Global Design Analysis Static & Dynamic Analysis, Buoyancy Modelling & Sensitivity Analysis, Global Fatigue Analysis, Dynamic Fatigue Testing, Cross Section Fatigue Analysis, Service Life Assessment and more.

Outlines

What is Flexible Pipe

Types of Flexible Pipe

Comparison of Flexible Pipe Types

Flexible Pipe Application

Advantages of Flexible Pipe

Flexible Pipe Limits

Flexible Pipe Configurations

Flexible Pipe Material Selection

Flexible Pipe Layer Function

Ending Fitting Design critical Issues

Flexible Pipe Design Process

Flexible Pipe Functional Requirements

Flexible Pipe Design Codes & Criteria

Flexible Pipe Structural Design

Flexible Pipe Local Structural Cross-Section Design & Analysis

Flexible Pipe Local Structural Cross-Section Design Models

Flexible Pipe Local Structural Cross-Section Design Models Advantages & Disadvantage

Flexible Pipe Layer Mass Determination using Axi-Symmetric Model

Flexible Pipe Layer Fraction Filled (Ff) Determination using Axi-Symmetric Model

Flexible Pipe Layer Axial Stress Determination using Axi-Symmetric Model

Flexible Pipe Layer Internal Pressure Determination using Axi-Symmetric Model

Flexible Pipe Layer Bending Stiffness Determination using Axi-Symmetric Model

Flexible Pipe Layer Minimum Bending Radius Determination using Axi-Symmetric Model

Flexible Pipe Layer Global Design Analysis Static Analysis

Flexible Pipe Layer Global Design Analysis Static Dynamic Analysis

Flexible Pipe Submerged (or ‘Apparent’ or ‘Effective’) Mass Analysis

Flexible Pipe Apparent Mass (AM) and Effective Tension Analysis

Flexible Pipe Buoyancy Modelling Analysis

Vessel Offsets & RAOs Analysis

Flexible Pipe Sensitivity Analysis

Environmental Waves & Parameters for Sensitivity Analysis

Flexible Pipe Global Fatigue Analysis

Flexible Pipe Dynamic Fatigue Tetsing

Flexible Pipe Cross Section Fatigue Analysis

Flexible Pipe Service Life Assessment

Computation of Mooring system natural frequency

Computation of FPSO Added Mass using first degree of freedom

Computation of Current Drift Force (Tonf) & Offsets (m) on FPSO

Computation of Wind Offsets (m) on FPSO

Computation of Mean Wave Drift (Tonf) & Offsets (m) on FPSO

Computation of Critical Damping in the System on FPSO

Computation of Actual Damping in the System

Computation of Maximum Drift During Storm (m) on FPSO

Technical Support Sectional References

Ref 1: Overview of SURF systems

Ref 2: Functions and applications of SURF

Ref 3: SURF systems environmental considerations

Ref 4: Components of subsea umbilical systems

Ref 5: Types of subsea umbilical systems

Ref 6: System requirements of subsea umbilical systems

Ref 7: Depth and pressure considerations of subsea umbilical systems

Ref 8: Material selection and corrosion protection of subsea umbilical systems

Ref 9: FEA and CFD in umbilical system design

Ref 10: FEA and CFD steps in umbilical system design

Ref 11: Fabrication techniques of subsea umbilical systems

Ref 12: Quality control and inspection of subsea umbilical systems

Ref 13: Terminations and end fittings of subsea umbilical systems

Ref 14: Installation techniques of subsea umbilical systems

Ref 15: Testing and commissioning of subsea umbilical systems

Ref 16: Failure Modes and Effects Analysis (FMEA) of subsea umbilical systems

Ref 17: Corrosion management of subsea umbilical systems

Ref 18: Non-destructive testing (NDT) of subsea umbilical systems

Ref 19: Inspection and maintenance of subsea umbilical systems

Ref 20: Repair and replacement of subsea umbilical systems

Ref 21: Components of subsea riser systems

Ref 22: Types of subsea riser systems

Ref 23: System requirements of subsea riser systems

Ref 24: Material selection and corrosion protection of subsea riser systems

Ref 25: Fabrication techniques of subsea riser systems

Ref 26: Quality control and inspection of subsea riser systems

Ref 27: Installation techniques of subsea riser systems

Ref 28: Testing and commissioning of subsea riser systems

Ref 29: Failure Modes and Effects Analysis (FMEA) of subsea riser systems

Ref 30: Corrosion management of subsea riser systems

Ref 31: Non-destructive testing (NDT) of subsea riser systems

Ref 32: Inspection and maintenance of subsea riser systems

Ref 33: Repair and replacement of subsea riser systems

Ref 34: Components of subsea flowline systems

Ref 35: Types of subsea flowline systems

Ref 36: System requirements of subsea flowline systems

Ref 37: Material selection and corrosion protection of subsea flowline systems

Ref 38: Fabrication techniques of subsea flowline systems

Ref 39: Quality control and inspection of subsea flowline systems

Ref 40: Installation techniques of subsea flowline systems

Ref 41: Testing and commissioning of subsea flowline systems

Ref 42: Failure Modes and Effects Analysis (FMEA) of subsea flowline systems

Ref 43: Corrosion management of subsea flowline systems

Ref 44: Non-destructive testing (NDT) of subsea flowline systems

Ref 45:Inspection and maintenance of subsea flowline systems

Ref 46: Repair and replacement of subsea flowline systems

Ref 47: Emerging Technologies and Future Developments in SURF Engineering

Ref 48: Real-world examples of SURF in operation

Ref 49: Lessons learned from past SURF projects

Ref 50: Emerging trends in SURF engineering

Ref 51: Future outlook for the industry

Assessment

Participant underpinning knowledge of subsea umbilical risers & flow-lines engineering will be accessed with short answer multiple-choice questionnaire and real time SURFs layers design and verification case studies at the conclusion of the course.

Outcome

Participants will gain an in debt understanding of Engineering of Subsea Umbilicals, Risers & Flowlines. They will also be able to function with minimum supervision as a Subsea SURFs Engineer for IOCs, subsea pipeline company contractor, vendor or installation company.

Professional Certificate

Issued directly by Chess Subsea Engineering Europe.

Participant may be presented for Offshore Petroleum Training Organization (OPITO) Certification.

How to Register

Click here to download registeration booklet on msword and email completed booklet to info@chesssubseaengineering.org directly.