Description

A subsea manifold is a key component of a subsea production system, responsible for routing and distributing fluids from subsea wells to production facilities on the surface. Subsea manifold structural design, verification, and validation engineering involves designing, testing, and verifying the structural integrity and reliability of subsea manifolds.

The following are some key aspects of subsea manifold structural design, verification, and validation engineering:

Design requirements: The design of subsea manifolds must meet specific requirements in terms of pressure, temperature, flow rate, and other factors. These requirements are typically defined by regulatory standards, industry best practices, and project-specific requirements.

Structural analysis: Finite element analysis (FEA) is used to evaluate the structural integrity of the subsea manifold, including stress, strain, and fatigue life analysis. FEA models are used to simulate various operational and environmental conditions, including pressure, temperature, and flow.

Material selection: Materials used in the construction of subsea manifolds must be carefully selected to ensure that they are resistant to corrosion, erosion, and other forms of degradation in the subsea environment. Materials selection is based on factors such as strength, corrosion resistance, and manufacturability.

Validation testing: Validation testing is conducted to verify the structural integrity and reliability of the subsea manifold. Testing typically includes hydrostatic testing, pressure cycling, and fatigue testing. Testing is conducted under simulated operational and environmental conditions to ensure that the subsea manifold can withstand the expected loads and stresses.

Quality assurance: Quality assurance is critical to ensuring that the subsea manifold meets design requirements and is fit for purpose. Quality assurance activities include inspection and testing of materials, manufacturing processes, and final products.

Overall, subsea manifold structural design, verification, and validation engineering is a complex process that requires a multidisciplinary approach, involving expertise in areas such as structural engineering, materials science, fluid mechanics, and environmental science. Successful engineering of subsea manifolds requires careful attention to detail and a commitment to safety, reliability, and performance.

Subsea manifold is an arrangement of piping and/or valves designed to combine, distribute, control, and often monitor fluid flow. Subsea manifolds are installed on the seabed within an array of wells to gather production or to inject water or gas into wells.

Subsea Manifold Structural Design, Verification, And Validation Engineering (SMSDVVE) Level 1 to Level 3 covers Subsea Manifold Systems, Manifold Components & Deployment Techniques, Applicable API Specs & Valves, Manifold Control Systems, Modules & Piping Systems, Subsea Manifold Templates & Well Configuration, Subsea Manifold Design And Analysis, Subsea Manifold Flow Assurance, Subsea Manifold Installation, Subsea Manifold Risk Based Inspection and more

SMSDVVE Level 1 to Level 3 is designed to provide detailed knowledge of subsea manifold structural design and verification engineering.

Course Outline

- Subsea Manifold Types

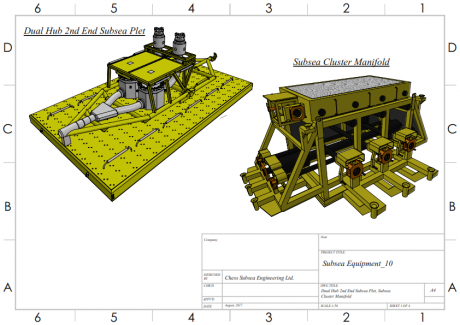

- Template Manifold

- Cluster Manifold

- Valves

- Pipework

- Control System

- Framework Structure

- Foundation

- Tie-Ins To Wells And Flowlines

- Insulation

- Deployment Methods

- Subsea Manifold Components

- Subsea Valves

- Valve Type

- Size and Pressure

- Control System

- Subsea Modules

- Piping System

- Templates

- Modular Template

- Manifold Template / Center

- Well Spacer /Tie-Back Template

- Riser-Support Template

- Steel Frame Structures Design

- Structural Design & Analysis

- Manifold Piping Design & Pigging Loop

- Padeyes & Control Systems

- Cp Design i.e. Materials for Hp/Ht and Corrosion Coating, Materials For Hp/Ht Manifolds, Material Evaluation &

- Metallic Materials

- Hydrate Prevention and Remediation

- Installation Capability

- Lifting and Lowering System

- Load Control and Positioning System

- Motion Compensation

- Installation Equipment And Installation Methods

- Crane Barge

- Dp Rig and Drilling Riser

- Other Installation Method

- Installation Analysis

- Barge Lift

- Splash Zone

- Transferring to A&R Wire

- Lowering In Deep Water

- Landing On the Seabed / Subsea Structure

- Degradation Mechanism i.e. Initial Assessment, Cof Identification, Risk Criteria & Outcome

- Detailed Assessment i.e. Safety Class, Pof Calculation, Target Criteria & Outcome

- Example for a Manifold Rbi i.e.Initial Assessment , Detailed Assessment & Inspection Plan.

2D and 3D Structural Design of a typical Subsea Manifold with Components using CAD Software such as Inventor or Solid Work

Assessment

Participant underpinning knowledge of Subsea Manifold Structural Design, Verification, and Validation Engineering will be accessed with short answer multiple-choice questionnaire at the conclusion of the course.

Professional Certificate

Issued directly by Chess Subsea Engineering Europe.

How to Register

Click here to download registeration booklet on msword and email completed booklet to info@chesssubseaengineering.org directly.