Description

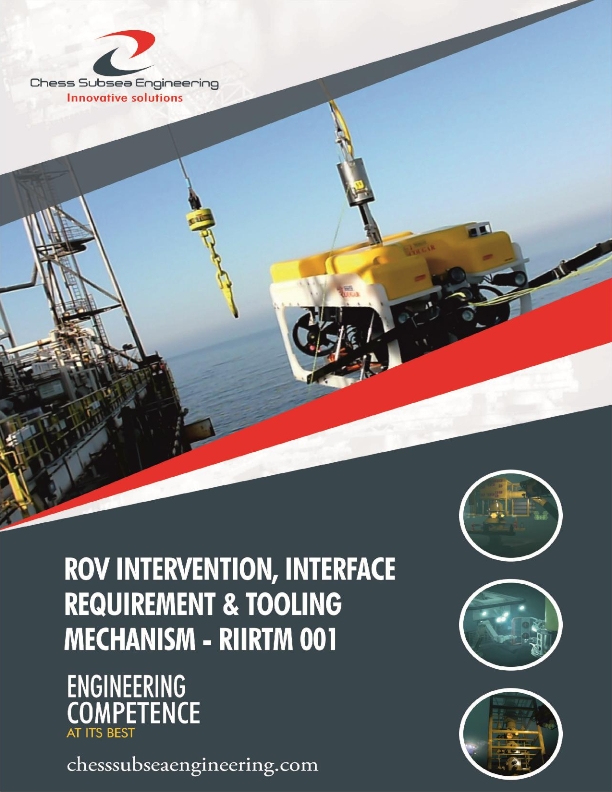

The ROV Intervention, Interface Requirement & Tooling Mechanism (RIIRTM) Level 1 & Level 2 course is a specialized training program focused on the knowledge and skills required to effectively operate remotely operated vehicles (ROVs) for intervention and tooling purposes in underwater environments.

The course covers various aspects of ROV operations, including ROV system components, control systems, underwater communication, interface requirements, and tooling mechanisms, providing participants with a comprehensive understanding of the ROV intervention process.

Participants gain practical knowledge of ROV operations, including maneuvering, navigation, intervention techniques, and tooling operations, allowing them to perform complex tasks and effectively support subsea operations.

The Level 1 course provides a foundation by introducing participants to the basics of ROV intervention and tooling mechanisms, while the Level 2 course delves deeper into advanced topics such as advanced tooling techniques, operational planning, and troubleshooting.

Through a combination of theoretical instruction, practical exercises, and simulation-based training, participants acquire the skills necessary to safely and efficiently operate ROVs, perform intervention tasks, and utilize specialized tooling mechanisms in various underwater applications.

ROV Intervention, Interface Requirement & Tooling Mechanism (RIIRTM) Level 1 & Level 2 covers overview of the state of the art for subsea remote intervention and vehicles, ROV technologies, and ROV capabilities and requirements for subsea operations, ROV Intervention Operations for Site Survey, Drilling Assistance, Installation Assistance, Operation Assistance, Inspection, Maintenance and Repair, ROV Intervention System, ROV Machine etc. ROV interface requirements based on API 17H, Remote-Operated Tool (ROT) and more.

Course Outlines

Overview of the state of the art for subsea remote intervention and vehicles

ROV technologies and capabilities

Requirements for subsea operations

Site Survey

Drilling Assistance

Installation Assistance

Operation Assistance

Inspection, Maintenance and Repair

ROV Intervention

ROV intervention systems

Interconnections & Characteristics

and configurations

Requirements ROV interfaces and is based primarily on API 17H

Hydraulic Work Package and Docking Frame

Hydraulic Connector & Valve Override Tool

Adapter for the ROV Manipulator

Subsea Systems

ROT Configuration, Generations of ROT for tie-in tools

Additional Support Technical Section

Ref 1: Overview of ROV systems and their applications in subsea operations

Ref 2: Types and classifications of ROVs

Ref 3: ROV components and their functions

Ref 4: Introduction to ROV control systems and communication interfaces

Ref 5: ROV intervention methods for subsea operations

Ref 6: Manipulator arms and tooling systems used in ROV interventions

Ref 7: Understanding ROV sensors and imaging systems for visual inspections and data collection

Ref 8: ROV navigation and positioning techniques

Ref 9: Subsea infrastructure and equipment interfaces for ROV operations

Ref 10: Interface standards and guidelines for ROV integration

Ref 11: Umbilical management and tethering systems

Ref 12: Power and data transmission requirements for ROV operations

Ref 13: Overview of ROV tooling mechanisms used for subsea tasks

Ref 14: ROV-mounted cutting, gripping, and sampling tools

Ref 15: Tooling interfaces and compatibility considerations

Ref 16: Safety protocols and procedures for ROV operations

Ref 17: Risk assessment and hazard identification in subsea environments

Ref 18: Maintenance and inspection practices for ROV systems

Ref 19: Case studies and lessons learned from real-world subsea projects

Ref 20: Overview of relevant industry standards and regulations governing ROV operations

Ref 21: Compliance requirements and documentation for subsea projects

Ref 22: ROV operations environmental considerations and mitigation measures

Ref 23: Exploration of emerging technologies in ROV systems

Ref 24: Trends in autonomous and unmanned subsea operations

Ref 25: Discussion on the future of ROV systems and their impact on subsea projects

Ref 26: Piloting Underwater ROV

Ref 27: ROV Operational Procedures

Ref 28: ROV Operations JSA

Ref 29: ROV Mobilization Procedures with JSA

Ref 30: ROV Demobilization Procedures with JSA

Ref 31: A case study of ROV Mobilization & Demobilization

Assessment

Participant underpinning knowledge of ROV Intervention, Interface Requirement & Tooling Mechanism will be accessed with short answer multiple-choice questionnaire at the conclusion of the course.

Outcome

Participants will gain an in debt understanding of ROV Intervention, Interface Requirement & Tooling Mechanism .They will also be able to function with minimum supervision as Offshore Engineers, Technicians & Subsea Engineers, Subsea ROV Technician, Subsea Project Engineer for IOCs, Offshore Drilling & Installation Contractors.

Professional Certificate

Issued directly by Chess Subsea Engineering Europe.

Participant may be presented for Offshore Petroleum Training Organization (OPITO) Certification.

How to Register

Click here to download registeration booklet on msword and email completed booklet to info@chesssubseaengineering.org directly.