Description

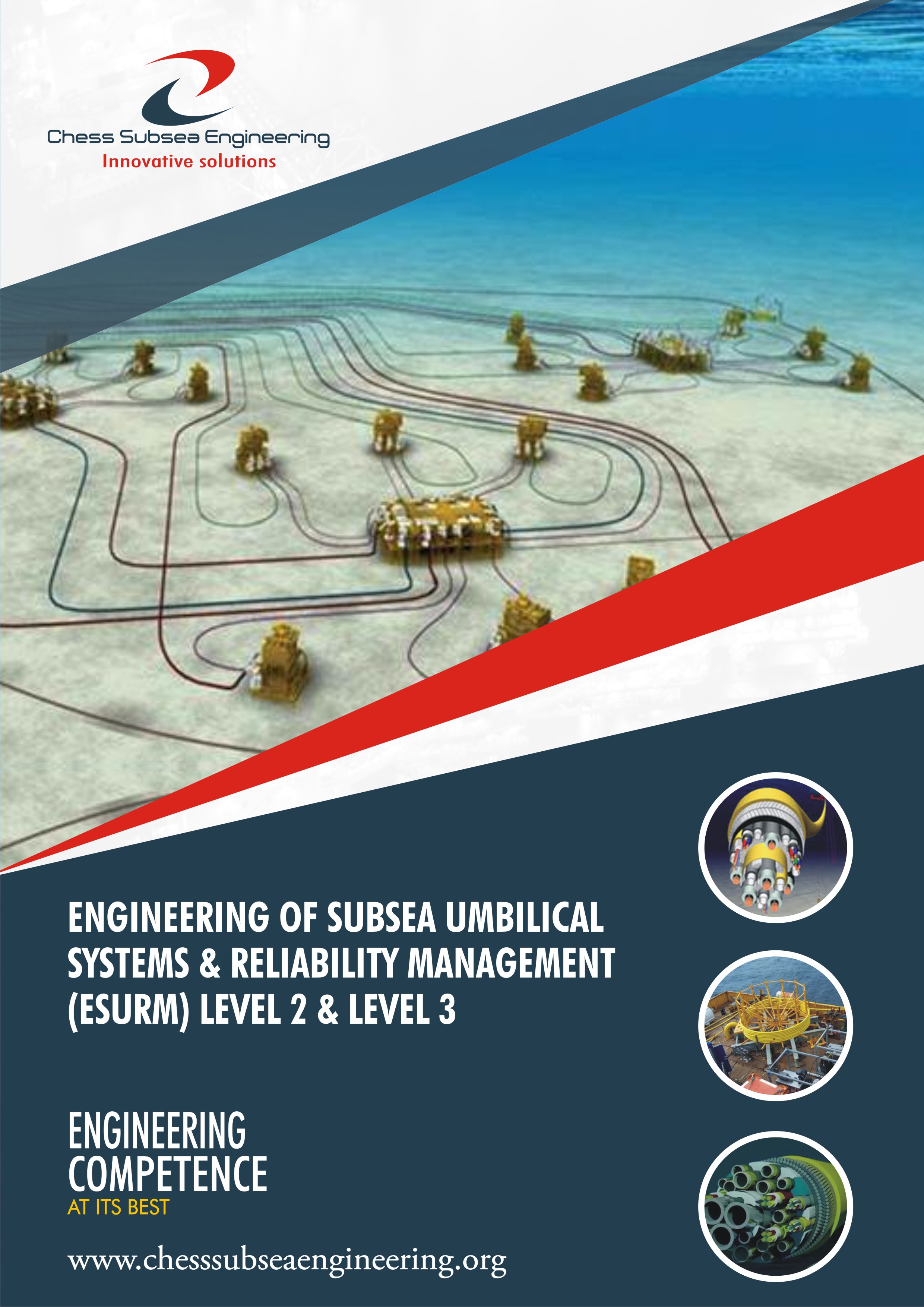

Engineering of Subsea Umbilical Systems & Reliability Management (ESURM) is a comprehensive framework that encompasses the design, construction, installation, and maintenance of subsea umbilical systems used in offshore oil and gas operations. It also includes the management of reliability throughout the lifecycle of these systems. The ESURM framework consists of three levels: Level 1, Level 2, and Level 3, each addressing specific aspects of engineering and reliability management.

Level 1 of ESURM focuses on the basic engineering principles and requirements for subsea umbilical systems. It involves the preliminary design and analysis of the system, including the selection of appropriate materials, components, and configurations based on the operational requirements and environmental conditions. Level 1 also includes the development of system specifications, performance criteria, and preliminary cost estimates. At this stage, engineering considerations such as pressure rating, temperature limits, corrosion resistance, electrical and hydraulic power requirements, and functional requirements are defined.

Level 2 of ESURM delves deeper into the detailed engineering of subsea umbilical systems. It involves the development of comprehensive engineering designs, including the layout, routing, and integration of umbilicals with other subsea equipment. This level encompasses the analysis and selection of specific components, such as hoses, electrical cables, steel tubes, and fiber optic lines. Detailed stress analysis, thermal analysis, and dynamic analysis are performed to ensure the structural integrity and operational reliability of the umbilical system. Level 2 also involves the development of detailed manufacturing, fabrication, and installation procedures, including quality control and testing protocols.

Level 3 of ESURM focuses on the management of reliability throughout the lifecycle of subsea umbilical systems. It encompasses the development and implementation of strategies to ensure the long-term performance and integrity of the systems. Level 3 includes reliability-centered maintenance (RCM) practices, periodic inspection and monitoring plans, risk assessments, and failure analysis techniques. It also involves the development of contingency plans and emergency response procedures to mitigate potential failures or accidents. Level 3 of ESURM emphasizes the importance of data collection, analysis, and continuous improvement to enhance the reliability and safety of subsea umbilical systems.

Engineering Of Subsea Umbilical Systems & Reliability Management Level 1 to Level 3 covers Overview of subsea umbilical components (power cables, hydraulic lines, fiber optics, etc.), Types of subsea umbilical systems (wet vs. dry, dynamic vs. static), Environmental factors (water depth, temperature, pressure, etc.) for subsea umbilical system, System requirements (power needs, data transfer, fluid transfer, etc.) for subsea umbilical systems, Depth and pressure considerations for subsea umbilical systems, Material selection and corrosion protection for subsea umbilical systems, Importance of FEA and CFD in umbilical system design, Applications of FEA and CFD in umbilical system design, Subsea umbilical systems FEA steps, Subsea umbilical systems CFD steps, Subsea umbilical systems fabrication techniques (wet-mate vs. dry-mate, injection molding, etc.), Subsea umbilical systems quality control and inspection during fabrication, Subsea umbilical systems Terminations and end fittings, Subsea umbilical installation techniques (laying, trenching, etc.), Risks and challenges of subsea umbilical installation, Remote operated vehicles (ROVs) and their role in umbilical installation, Importance of testing and commissioning of subsea umbilical, Subsea umbilical protection and installation accessories (e.g., bend restrictors, clamps, connectors), Types of tests (electrical, pressure, etc.) for subsea umbilical, Subsea umbilical commissioning procedures, Subsea umbilical failure Modes and Effects Analysis (FMEA) and other reliability assessments, Subsea umbilical system corrosion management, Subsea umbilical system Non-destructive testing (NDT), ROVs and underwater inspections and maintenance of Subsea umbilical system, Subsea umbilical repair and replacement, Real-world examples of subsea umbilical systems in operation, Lessons learned from past subsea umbilical systems projects, Future developments in subsea umbilical advancements in materials and coatings, Future developments in subsea umbilical remote monitoring and control systems, Future developments in subsea umbilical cost reduction and improved performance and more.

Course Outlines

Subsea Tube Umbilical & Control

System, Feasibility Study

Detailed Design and Installation

Qualification Tests

Control System & Elements

Umbilical Technological Challenges and Solutions

Cross-sectional Design of the Umbilical

Steel Tube Design Capacity Verification

Allowable Bending Radius

Extreme Wave Analysis

Manufacturing Fatigue Analysis

Accumulated Plastic Strain

Low Cycle Fatigue

In-place Fatigue Analysis

Selection of Seastate Data from Wave Scatter Diagram

Analysis of Finite Element Static Model

Umbilical Fatigue Analysis Calculations

Simplified or Enhanced Approach

Generation of Combined Stress History

Rainflow Cycle Counting Procedure or Spectral Fatigue Analysis

Installation Analysis

Required On-Seabed Length for Stability

Subsea Umbilical Asset Integrity Management

Technical Support Sectional References

Ref 1: Definition and purpose of subsea umbilicals

Ref 2: Overview of subsea umbilical components (power cables, hydraulic lines, fiber optics, etc.)

Ref 3: Types of subsea umbilical systems (wet vs. dry, dynamic vs. static)

Ref 4: Environmental factors (water depth, temperature, pressure, etc.) for subsea umbilical systems

Ref 5: System requirements (power needs, data transfer, fluid transfer, etc.) for subsea umbilical systems

Ref 6: Depth and pressure considerations for subsea umbilical systems

Ref 7: Material selection and corrosion protection for subsea umbilical systems

Ref 8: Importance of FEA and CFD in umbilical system design

Ref 9: Applications of FEA and CFD in umbilical system design

Ref 10: Subsea umbilical systems FEA steps

Ref 11: Subsea umbilical systems CFD steps

Ref 12: Subsea umbilical systems fabrication techniques (wet-mate vs. dry-mate, injection molding, etc.)

Ref 13: Subsea umbilical systems quality control and inspection during fabrication

Ref 14: Subsea umbilical systems Terminations and end fittings

Ref 15: Subsea umbilical installation techniques (laying, trenching, etc.)

Ref 16: Risks and challenges of subsea umbilical installation

Ref 17: Remote operated vehicles (ROVs) and their role in umbilical installation

Ref 18: Importance of testing and commissioning of subsea umbilical

Ref 19: Subsea umbilical protection and installation accessories (e.g., bend restrictors, clamps, connectors)

Ref 20: Types of tests (electrical, pressure, etc.) for subsea umbilical

Ref 21: Subsea umbilical commissioning procedures

Ref 22: Subsea umbilical failure Modes and Effects Analysis (FMEA) and other reliability assessments

Ref 23: Subsea umbilical system corrosion management

Ref 24: Subsea umbilical system Non-destructive testing (NDT)

Ref 25: ROVs and underwater inspections and maintenance of Subsea umbilical system

Ref 26: Subsea umbilical repair and replacement

Ref 27: Real-world examples of subsea umbilical systems in operation

Ref 28: Lessons learned from past subsea umbilical systems projects

Ref 29: Future developments in subsea umbilical advancements in materials and coatings

Ref 30: Future developments in subsea umbilical remote monitoring and control systems

Ref 31: Future developments in subsea umbilical cost reduction and improved performance

Assessment

Participant underpinning knowledge of Engineering Of Subsea Umbilical Systems & Reliability Management (ESURM) Level 2 & Level 3 will be accessed with short answer multiple-choice questionnaire and case studies at the conclusion of the course.

Professional Certificate

Issued directly by Chess Subsea Engineering Europe.

Participant may be presented for Offshore Petroleum Training Organization (OPITO) Certification.

How to Register

Click here to download registeration booklet on msword and email completed booklet to info@chesssubseaengineering.org directly.