Purpose

To develop the highly specialized skills and knowledge required for Instrumentation & Control for Offshore Engineers & Technicians at Level 1. ICOOET Level 1 is meant for those who presently possess some electrical knowledge, work in a maintenance environment and seek to expand their activities to include process control and instrumentation systems.

ICOOET Level 1 has been fully subsidized and offered in accordance to Nigerian Local Content and Department of Petroleum Resources (DPR PERMIT NO: DPR/OGISP/20/9988489/N186827) requirements on engineering training and manpower development indigenously.

If you are immediately available and have passion to join the instrumentation & control industry, why not join our Accelerated Production Process Instrumentation & Control OJT Programme for Technicians & Field Engineers (APPICTFE) Level 1 to Level 2. This course is organized by Chess Subsea Engineering Europe in partner with her technical partner in Nigeria based on manpower training and development indigenously.

“I & C systems, if properly programmed, can be the brains of your operation”

Objectives

To provide to the student the knowledge and skills required for production instrumentation & control position and perform the assigned tasks safely and efficiently.

Synopsis

Proper troubleshooting and maintenance of plant systems & equipment to reduce downtime and save money requires more than just replacing parts when they get broken. In fact, a “replace- part-when-broken” strategy for maintaining equipment is frequently the most expensive approach you can take. To be effective, maintenance technicians who fix equipment must know why a part needs to be changed out in the first place.

Accelerated Production Instrumentation, Process Measurement and Control two (2) months on the job training Programme; students will learn what, where and how to measure parameters for the proper monitoring and control of their equipment. When breaks, they’ll now know why. With this understanding, they will be able to work much more efficiently on the industrial systems and processes for which they are responsible.

A sound knowledge in instrumentation and control is certain to result in better-qualified technicians and less equipment failures.

Benefits

The attendees will learn about:

- Basics of I & C, including different control functions, types of control loops and continuous vs. discrete control.

- Identification and symbols used in I & C.

- Different types of field instrumentation, their principles of operation, their advantages and disadvantages and the application of the different types of sensors for flow, level, pressure and temperature measurements.

- Requirements for control rooms and the design of control panels.

- Concepts and implementation of alarm and trip systems.

- Different types of computer-based control systems, including PLCs and DCSs, as well as basic requirements for good operator interface.

- Documentation required for I & C for front-end engineering and detail design.

- Requirements for a successful installation, instrument checkout and controller tuning.

- Project implementation and project management.

- Decision-making tools, namely, Auditing, Evaluation of Plant Needs, Justification, and Control System Evaluation.

Target Audience

This program is for those who want to learn about the I & C field in a condensed time frame and from a practical point of view and/or for those who simply want to communicate technically with I & C personnel.

It is designed to provide attendees with sufficient knowledge to move into the field of I & C. It is applicable to technical and supervisory personnel. It is presumed that participants come from a setting where they can apply the knowledge received.

Instrumentation & controls are quite useful to a wide variety of fields of technology: engineering, oil and gas, medical, aviation, media, consumer electronics, computers (IT), etc.

The course will allow you to:

- Make an immediate impact at your company

- Access resources that will help you throughout your career

- Get practical, hands-on experience to keep yourself proficient

- Stay up to date on the latest Instrumentation and Control standards

Course Content

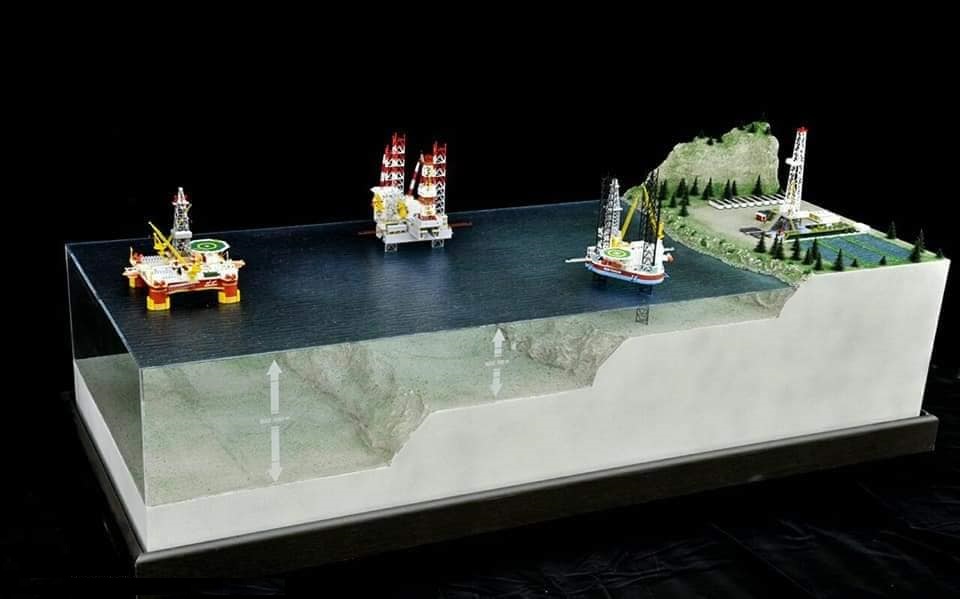

Subsea Production Systems

Subsea Field Architecture

Subsea Distribution Systems

Subsea Structures and System Integration

Process Control

Control Loop & Components

Control Loop Classifications

Closed and Open control loops

Automatic and Manual control

Piping & Instrumentation Diagrams

Measurement Terminology

Measuring Instrument

Calibration Terminology

Intrinsic Safety

Electrical Control Loops

Pressure Overview

Pressure Measurement Devices & Sensors

Flow Measurement Devices

Differential Pressure Flow Measurement

Velocity Flow Meters

Mass Flow Measurement

Level Measurement

Types of Level Mesaurement

Hydrostatic Head Level Measurement

Displacer

Ultrasonic & Radar

Nuclear Level Instrument

Temperature Units

Thermometers

Bimetallic Strip

Filled Thermal System

Resistance Temperature Detector (RTD)

Thermistor & Thermocouples

Thermocouples Types, Construction & Tip Styles

Thermowells & Infrared Thermometers

Thermography

Control Valve Components

Basic Valve Components

Control Valve Body & Classification

Types & Classification of Actuators

Valve Failure Mode

Control Valve Accessories

Hand Wheel / Manual Lever

Transducer and Volume Booster

Solenoid Valve

Fail Safe Systems & Limit Switches

Quick Exhaust Valve & Positioner

Digital or Smart Devices

Control Loops and Controller Action

Control Schemes & Types

“Extensive practices & hand on experiences”

Assessment

Participant underpinning practical knowledge of Production Process Measurement Instrumentation & Control Mastery will be accessed.

Outcome

Participants will gain an in debt understanding of Production Process Measurement Instrumentation & Control Mastery. They will also be able to function with minimum supervision as instrumentation & control technicians at oil and gas production site regardless of location.

Professional Certificate

Issued directly by Chess Subsea Engineering Europe upon competence assessment from client.

Training Methodology

All the trainings & workshops are interactive and include the following training methodologies as a percentage of the total tuition hours:- .

15% Lectures

75% Workshops & Hands On

5% Competence Assessments

5% Videos & General Discussions

Training Mode

Our modes of training includes:

- Instructor-led classroom

- Interactive methods

- Hands-on

- Computer-based and e-learning

- Videos

- Coaching and mentoring.

Offline : Portharcourt Only

No 5 Off Rumoula Link Road, Rivers State, Portharcourt, Nigeria

Note: Rotational training and hands on workshop will be at our indigenous partners location

In House & Offline Training Mode

Six (6) days of eight (8) hours intensive training to gain theoretical concept followed by five (5) days practical intensive hands on experience at end clients workshop. Competence to be accessed daily globally

Course Training Dates

- Start Date Offline: –

Maximum No Of Participant (In House Only) Per Session: 5

Course Fees

- Offline: N 300, 000 Naira Only

Installmental Payment Acceptable (2 Times Only)

50% | 50%

How to Register

Click here to download registeration booklet on msword and email completed booklet to info@chesssubseaengineering.org directly.

Testimonials

Exceeding Customer Expectations via our On the Job Training (OJT) Online & Offline

We are the first choice for subsea engineering and training in the oil, gas and renewables and we stand out thanks to the quality of our technical capabilities and excellent customer service.

Engr. Michael Frank Oyakhilome Idode

Senior Civil & Structural Engineer, Shell, Nigeria

CADDAS Engineering programme (online option) was very practical, informative and eye-opening to deep & ultra deepwater structures design & Simulations.All areas where covered brilliantly.

Engr. Williams Aiyemo

Assets Integrity Management Fixed Equipment Engineer, Chevron, Nigeria

CADDAS Engineering programme (online option) has exposed me to various aspects of subsea operations, design of subsea equipment, use of various software to aid equipment design, asset integrity management of subsea equipment and safety requirement of subsea operations. The trainers have versatile knowledge of the courses, and for every of the modules taken, the always displayed keen interest to make it as practicable as possible, kudos to them on there wreath of experience."

Engr. Kalio Joseph

Senior Production Engineer at Oando Plc, Nigeria

"Subsea Controls, Hydraulics, SURFs & Subsea Structures Installation Master Class (SCHSSSIMC) Level 1 to Level 3 assignments were well designed and very good learning tools. The course has the right blend of theoretical and practical knowledge."

Ikechukwu Ubochi

Roustabout/ NDT Inspector at Ophily Oil & Gas Nigeria Limited

"I have completed my ICOOET Level 1 & Level 2 course. Course instructors were great, practicals were delivered excellently, training lectures were well organised and the training class were conducive for learning. Am fully satisfactory and I want to say a big thanks you to Chess Subsea Engineering for the knowledge that they have imparted on me."

Inuwa, Idris Umar

Project Engineer (Pipelines and Facilities) Oilserv Limited, Port Harcourt, Nigeria, Africa

What a rewarding and fulfilling experience!!!. OETTG Level I & Level II program (online option) really exposed me to the various aspects of the offshore environment, technicalities, challenges, operations and engineering aspects of oil and gas platforms, drilling, production, processing, storage and transportation of oil and gas offshore.Indeed, the training cut across the entire value chain of offshore technology and engineering for beginners and entry-level graduates. Really appreciate my online instructor (Engr. Osaghale, O.) for his efforts, enthusiasm and professionalism. Chess Subsea Engineering is indeed the future of oil and gas training and development for the next generation oil and gas professionals.

Daniel Olatunde Obadaye

Managing Director / Team Lead, Erde Ocean Energy Limited, Nigeria, Africa

"Chess Subsea Engineering provided Training service on Subsea Survey, Systems Positioning and Metrology (SSSPM) Level 1 & Level 2 for our Personnel in Port Harcourt Nigeria, West Africa. The standard of training service provided by Chess Subsea Engineering has been high and their personnel are well experienced in the type of works being undertaken. They have been very helpful and proactive, this further compounded by them, successfully adapting industry high standard training to satisfy the additional requirements in Oil and Gas sector."

Engr Promise Ihunwo

Petroleum & Production Engineer, Jubob Engineering Limited, Nigeria, Africa

"My training with Chess Subsea Engineering on Offshore Engineering & Technology for Technicians and Graduates (OETTG) Level 1 and Level 2 has further expanded and garnered knowledge on Offshore Engineering operations & Processing Technology, Well control and Surface facility protection, Wellhead Platforms, Well Monitoring and control using RTU and SCADA. I have garnered experience in the Offshore New Technologies that involved intelligent well completion, digital oil filed via SCADA, multiphase pumping, components of subsea production control system and subsea processing. The architectural design of Umbilical & chemical injection system and topside & subsea control system evaluation were not left out. "

Okoh Ambrose Omuye

Mechanical Engineer, Mantrac Nigeria Limited,Africa

"Chess Subsea Engineering instructors offers top – notch quality, service and second to non-rates across the board, in the course of my trainee, I was trained on platforms, different types of platforms, Maintenance and Supply, Crew, Facilities in Well Platforms, Pneumatic Control Panels, Fire and gas leakage protection system, Surface Facility Protection, Well control & Protection, SMART Wellhead Platforms, Well Monitoring and Control RTU / SCADA, Major Benefits of SCADA, Separation (Oil, Gas and Produced water) & Oil dispatch, Gas Compression & dehydration, Produced Water Conditioning, Sea water processing & injection system, Fire Detection & Suppression System, Utilities Offshore, Intelligent wells, Digital Oil Field via SCADA, Multiphase Pumping, Subsea Processing and more. I am always pleased with the illustration and attention to details always given by my instructor Engr. Lucas in the course of the training."

Abimbola Fatai Akorede

Doctorate Well Engineering Postgraduate Student

China University of Petroleum, Beijing, China

"I took Well Engineering and Construction for Graduate and Field Technicians (WECGFT) Level 1 training. The course content was detailed and included introduction to well engineering, well construction, drilling rig types, drilling rig major components, well drilling operations and cementing. The course is adequate to equip one with basic skills and knowledge of fundamentals of well engineering. I look forward to having more Well Engineering trainings Chess Subsea Engineering offers."

Izuchukwu Obi

Civil Engineer, West Africa, Nigeria

"Very helpful training in understanding how the offshore industry works. Simple, easy-to-follow lectures and course materials. I strongly recommend OETTG Level 1 & Level 2 for graduates or technicians switching or enhancing their career offshore"

Kelvin Ernest Yankey

NACE Certified CIP, Technical Sales

PrepCoat Global Services Ltd, Cantonments, West Africa, Accra-Ghana

"My experience with OOCEC Level 1 & Level 2 online training was great. The instructor was well prepared and ready to share knowledge with me We had a good time discussing corrosion, causes and mitigation techniques."

Fademi Ekundayo Oluwademilade Jacob

Operations Engineer, IHS Towers, West Africa, Nigeria

"I want to appreciate the entire Chess Subsea Engineering Team for organizing and putting together this class. It is a good medium for recent graduates and developing professionals to develop themselves and grow in their respective careers. I cannot give any recommendation as to how any part of the program can be improved. Right from the registration to the lectures, every process was seamless."

Animashaun Musa Bolarinwa

Surveyor, Geodetic Offshore Services Limited, Africa

"The Subsea Survey, Systems Positioning and Metrology (SSSPM) Level 1 & Level 2 training was very enlightening and insightful. It expanded my knowledge of Underwater Acoustic Positioning and Subsea Metrology. I appreciate Chess Subsea for putting up such educative platform while utilizing highly experienced facilitators and cutting-edge resources."

Edward Oluwasegun Oyelade

Trainee Data Processor / Geophysicist, Africa

"Through the SSSPM Level 1 & Level 2 training I was able to connect a lot of my previous knowledge of seabed survey and the gas industry into a big picture of how they operate. I was adequately introduced to metrology with patient description of subsea facilities, the metrology process, terms, and industry standards. I was also exposed to aspects of systems positioning systems new to me. As an aspiring geophysicist, I can say for sure that I have become more knowledgeable of subsea activities."

Odafe Abade

Graduate Production Engineer, Sterling Oil Exploration & Energy Production Company (SEEPCO) Limited, Africa

"I just completed the Natural Gas Engineering Production Process (NGEPP) Level 1 & Level 2 and I must say it has been an insightful experience and a great opportunity to learn new things. My tutor was very thorough with the course outline, his explanation was comprehensive and I really loved how he supported each topic on the course outline with videos in order for to grasp a virtual view of all the processes involve in natural gas processing."

Adelina Adao

Gas Engineer, Betchel, Angola, Africa

"I found the Natural Gas Engineering Production Processes (NGEPP) Level 1 & Level 2 interesting, challenging, and rewarding. I learnt a lot by following the course set out including Oil and Gas Seperation, Gas Dehydration, Petroleum Gas Compression, Natural Gas Liquid Recovery, Oil Pumping and Metering & Water Injection. Assignments were corrected quickly, with lots of positive feedback from the tutors."