Chess Subsea Engineering FluidmechTM is entirely committed in setting a benchmark in work ethic, Professionalism, Attitude, Team Work, Camaraderie, we build healthy and friendly work environment with customers which makes us incomparable with competitors.

Chess Subsea Engineering FluidmechTM stands away from others, as it works on challenging projects be it a Weight reduction of Machineries, Design Optimization of a product, New product development, Root cause Analysis and contour measure for better performance. We are well known for solving complex problems of Automotive, Aerospace, Naval, Defence Research Laboratories, Oil and Gas, Machine Manufacturers, Medical, Food Industries as well, It has proven past 7 years. We serve more than 70 customers across the globe.

Product Development

New Product Development, 2D to 3D Conversions, software migration,concept design, Detailing, Reverse Engineering and Tool Design.

Computational Fluid Dynamics

Transient and steady state flow, Conjugate heat transfer, Fluid Structure Interaction, Multiphase flow, Heat transfer. Multicomponent mixing

Finite Element Analysis

Linear, Non Linear, Fatigue, Buckling, Explicit & Implicit Analysis, Frequency response, Crash simulation. Design recommendation

Thermal Simulation

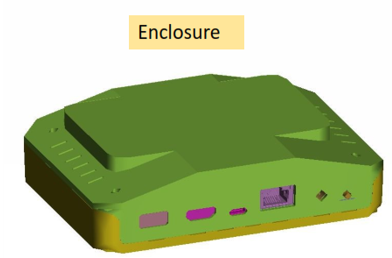

Thermal simulation for PCB along with enclosure assemblies for effective heat removal. Thermal optimization

Value Analysis & Value Engineering

Tear down assembly, Alternate sourcing, & materials, weight reduction, cost reduction increase profit.

Mold Flow & Mold Design

Fill time, Shrinkage. Warpage, Air trap, injection pressure simulation and Mold design.

FluidMechTM Services

- Weight Reduction

- Design Change Recommendation

- Design Optimization

- Cost Reduction

- Product Performance Enhancement

- Field Failure Prevention

FluidMechTM Remote Client Support Services

Support clients for Design, Simulation, Validation, Product Performance Enhancement, Weight Optimization, Cost Reduction.

- New product Development & CAD

- Finite element Simulation

- Computational Fluid Dynamics Simulation

- Thermal Simulation

- Design Optimization

- Weight optimization

- Cost reduction

- Field failure prevention

- Product performance enhancement

- Reverse Engineering

- Process Automation

Why Chess Subsea Engineering FluidMechTM

- 70 + Happy customers

- More than 450 projects delivered.

- Consistency and sustainability from 7 years

FluidMechTM Case Studies

Heat Transfer Optimization Case Study

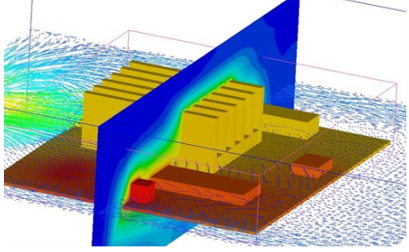

Objective: Maximize heat transfer to keep the electronic assembly temperature in control by carrying out the Design of experiments.

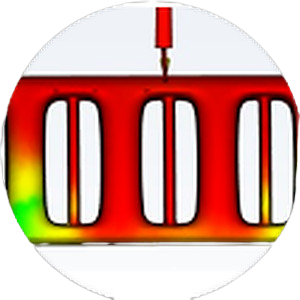

Thermal analysis results displaying the temperature contour and the movement of the air (velocity vectors) around heat sink and PCB.

FluidMechTM Project Executed in Thermal Simulation

- BLDC motor controller thermal Simulation

- Effective cooling of Aircraft Black boxes

- LRU units

- Heat sink optimization

- Engine Head conjugate heat transfer Simulation.

- Thermal Simulation for pressure transducer assembly.